VISION

The $600 billion single-family housing market demands change, and automation is the way to tackle the housing crisis. With hands-on experience in design and construction, we know how complex the process can be, typically involving 15-20 subcontractors. Instead of claiming to revolutionize the process, we focus on adapting robotics that can smoothly integrate into existing on-site workflows, helping home builders boost ROI immediately and simplifying tasks for other trades.

Linesbar empowers home builders with robotics, enabling much faster, more cost-effective, and sustainable project delivery by automating the most labor-intensive stage of construction: wall building. Our robot executes every step of wall construction, delivering high-quality, finished walls directly on-site with unmatched speed.

OUR WALL CONSTRUCTION TECHNOLOGY

Reduces wall construction time by 90%

CONCRETE

3D PRINTING

INSULATION

FINISHING

PRODUCT

More Than a Robot – A Partner in Construction. Our patented technology automates every step of wall construction: from concrete 3D printing to thermal and hydro insulation, finishing, and surface smoothing. By streamlining these critical tasks, we enable full automation of the wall construction process, reducing wall build times by up to 90% and overall project timelines by 20%, helping builders achieve unparalleled efficiency and quality.

PROCESS

Our robotic solution integrates into existing on-site workflows, simplifying tasks for other subcontractors. The process is divided into three key steps:

On-site Setup. Our team delivers the robot, supplies equipment and materials, sets it up on the foundation, and prepares it for wall construction.

Wall construction. The robot 3D prints concrete walls, leaving precise voids for MEP systems based on the CAD model. I then apply thermal and hydro insulation, followed by stucco for exterior walls and plaster for interiors, simultaneously smoothing surfaces for a polished finish. This cycle is repeated as needed.

Relocation. Once the walls are completed, the robot is cleaned and prepared for relocation to the next site, allowing subcontractors to start their tasks immediately.

ADVANTAGES

While reducing construction time and increasing profit margins are key for builders, the advantages for homebuyers are just as compelling. Through faster construction and automated labor, we’re not just transforming how homes are built—we’re elevating the entire experience for homebuyers. From custom designs at no extra cost and dramatically lower energy bills and maintenance expenses to fire- and hurricane-resistant walls, we deliver products built to last, ensuring peace of mind for years to come.

AFFORDABLE BESPOKE DESIGN

LOW MAINTENANCE COSTS

NATURAL DISASTERS RESISTANCE

LOW ENERGY BILLS

PROTOTYPE

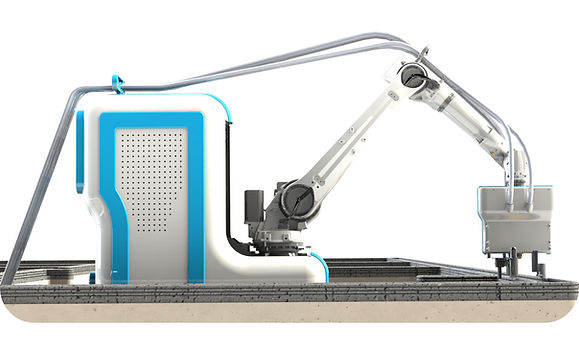

Developed to explore automation concepts for wall construction, our initial prototype includes an AGV, robotic arm, and an extruder, with a custom-made control system and sensors, all designed, produced, and assembled from scratch. The team has meticulously examined every aspect of the process, from optimizing the concrete mix formula to fine-tuning equipment settings, allowing for smarter and more efficient product design decisions.

TEAM

A common vision unites our team: to innovate construction through automation, solving today’s challenges, unlocking new design opportunities and contributing to a solution for the housing crisis.

With multidisciplinary expertise in architecture, robotics, and 3D printing, our team approaches product development from various angles, ensuring it is practical, efficient and valuable for construction sites.

.png)

.jpg)